Our workshop facilities and services include

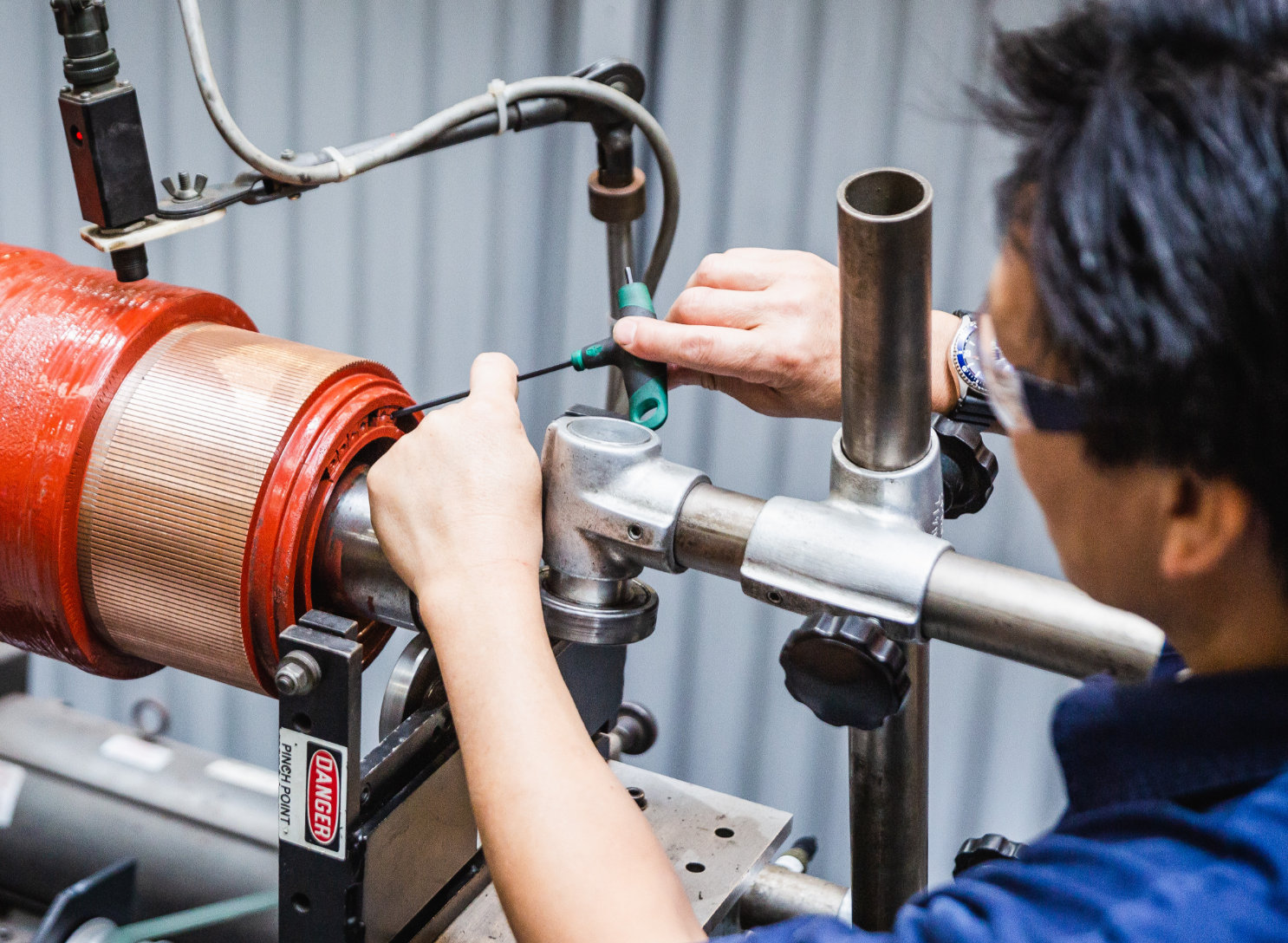

- Servicing and repairs to electrical and mechanical rotating equipment – AC/DC motors, pumps, industrial gearboxes, 400Hz static and rotary generators, fans and more.

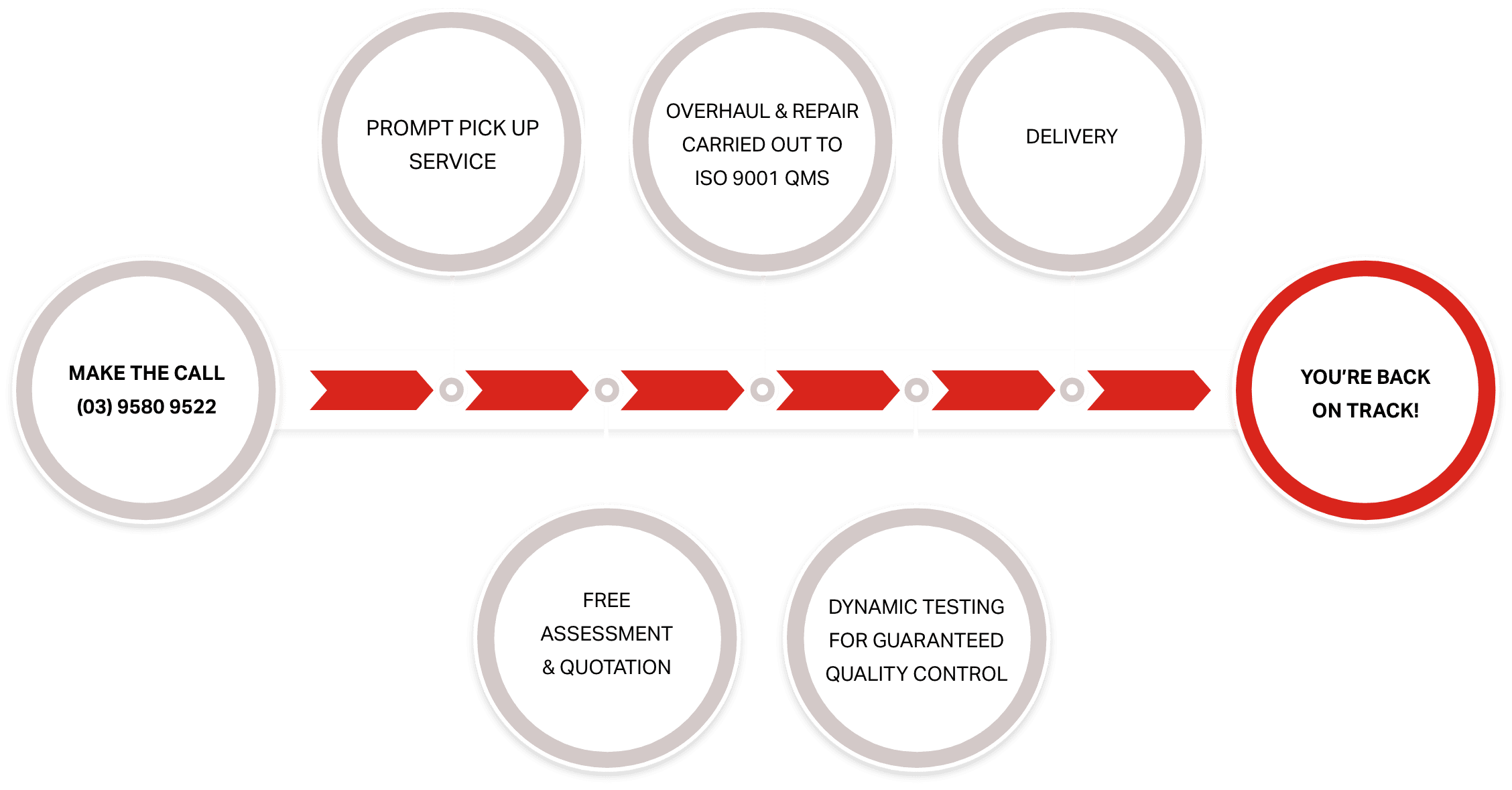

- Motor winding surge, Hi-pot and PI testing conducted on all rewinds and overhauls.

- In-house machining and engineering.

- Precision-controlled winding burn out oven.

- Dynamic balancing of rotating equipment

- Comprehensive test bay for the static and dynamic testing of AC and DC motors once repaired.

- Rewinding of irreplaceable ad specialised machinery.

- Modifications to suit customised applications with complete EMSPEC registry.

- Precision winding machines with winding data analysis.

- Dynamometer Load testing.

- EPA-approved cleaning facilities